HIGH NOISE IMMUNITY

Application of correlation reception of signals, error controlled codes, binary phase-shift keying and higher frequencies ensures the stability of the RAIL TRACK 300 circuits to the effects of traction harmonics and other electromagnetic interference. This reduces significantly the risk of false signal of the occupied block section or point section, resulting in failures in the transportation process. False vacancy signal resulting in violation of the safety rules for train traffic is excluded.

LOW OPERATING COSTS

The RAIL TRACK 300 track circuit is adjusted once when the track circuit is put into operation due to the semi-automatic selection of the receiver sensitivity using the configuration key and adjustment shunt. Re-adjustment due to changes in the insulation resistance of the track circuit is not required. This reduces the human factor impact on train traffic safety.

HARMONIZATION

The system is able to interact with the most systems of higher automation level and to adapt to connection to the existing wayside infrastructure of track circuits. The nomenclature of receivers and generators is minimal: one receiver and one generator, regardless of frequency.

TECHNICAL CHARACTERISTICS

The system is able to interact with most signaling systems of a higher level and can be adapted to connect to the existing wayside infrastructure of track circuits. The range of receiving terminals and generators is minimal — one receiver and one generator irrespective of frequency.

Characteristics of track circuits (the basic product and adaptation to the environment of the Russian Railways):

|

Characteristics

|

The basic product

|

After adaptation

|

|

The length of a track circuit

|

From 50 m to 2 км

|

From 25 m

|

The area of additional shunting

|

20 m

|

Up to 1,8 km 40 m

|

Minimal specific resistance of the track line insulation

|

2 Ohm·km

|

1 Ohm·km

|

Maximum resistance of the train shunt

|

0,15 Ohm

|

0,06 Ohm

|

|

Rail breakage detection

|

No

|

Yes

|

Interface with ATP

|

No

|

Yes

|

Russian track interface components

|

No

|

Yes

|

|

Correspondence to the Russian national frequency standards

|

Partial

|

Full

|

Operation temperature range

|

—30...+70 °С

|

—30...+70 °С

|

Core section of signaling cable

|

3,08 mm²

|

0,64 mm²

|

|

Seasonal adjustments

|

Twice a year

|

Not required

|

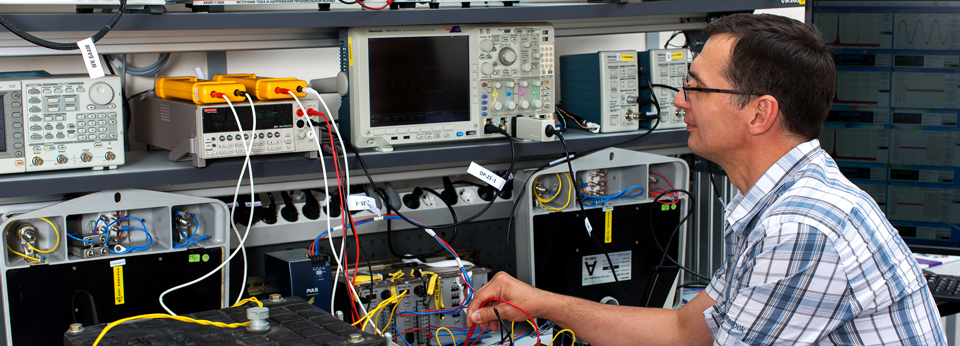

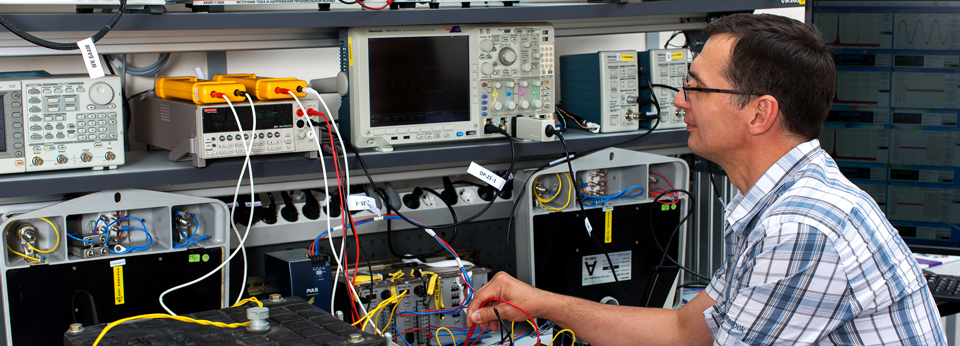

LABORATORY OF TRACK CIRCUITS

Our company has scientific, engineering and laboratory facilities at its disposal to carry out science-based works in the field of track circuits in the following directions:

The laboratory of track circuits is equipped with unique precision equipment that makes it one-of-a-kind in the industry. The tasks of experimental determination of relay interlocking properties, analysis of receiving equipment resistance to traction current noise, research of the noise level of relay interlocking and ATP on a rolling stock, track and at a traction substation can be solved at a high metrological level with the help of measurement and registration equipment.

The laboratory has high-qualified and experienced specialists who have been successfully developing relay interlocking and providing electromagnetic compatibility for many years and who are ready to solve the problems of the industry. Currently, the laboratory is working on the adaptation of the RAIL Track 400 track circuits for the Russian Railways.