决方案

ELECTRIC CONTROL OF WAYSIDE OBJECTS

Contactless interface allows regulating electric power supply of the controlled object in such a way that the voltage is always applied in the moment of zero phases, which means that voltage and current steps caused by commutation are excluded. It allows reducing tear-and-wear of wayside objects and eliminating the necessity of regular maintenance. All object controllers are equipped with a built-in diagnostic system that is fast to detect failures in operation and fault conditions of the wayside equipment.

CENTRALIZED AND DECENTRALISED PLACEMENT

Each object controller can control several wayside objects and can be positioned either centralized together with the central processor or decentralized (distributed) close to the controlled wayside objects. With distributed object controllers, cabling is kept to a minimum that is not only a cost-effective benefit, but also a reduction of the risk of induced currents that might cause signal interference.

The maximum distance between object controllers and the central processor is determined by the type of data transmission equipment and can reach up to hundreds of kilometers that makes it possible to engineer cost-effective systems with a high level of centralized traffic control. Data exchange between object controllers and the central processing unit is performed with the help of the standard network technologies (Ethernet 10Base-T, 100 Base-T) and UDP/IP protocol.

HIGH RELIABILITY AND SAFETY

Equipment of the object controller system is located in standard pre-installed cabinets and premises. Electric components have space effective design (up to 16 object controllers of different types can fit in one cabinet) and are tested for their compliance with the standards, required for signaling equipment in Europe and CIS countries (CENELEC). The safe operation of object controllers is achieved through software diversification.

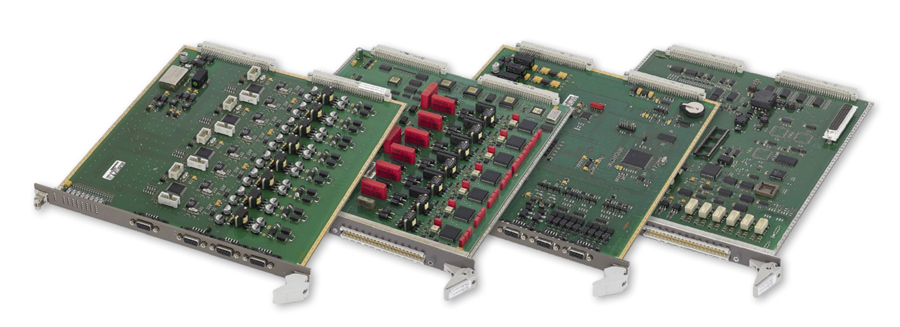

OBJECT CONTROLLERS BOARDS

Printed object controller boards are manufactured using a complicated multi-layer mounting technology (6 layers) on modern equipment. Control of product quality and manufacturing processes is exercised in accordance with the latest international standards. Due to this, object controller boards have increased reliability, functionality, a wide range of operational temperatures and resistance to different environments. The system can be equipped with surge protection devices.

CONTINUOUS DEVELOPMENT

The object controller system is constantly developing and obtaining new functions. One of the latest achievements is the ACE object controller that allows full integration of indoor equipment of the axle counter system into the object controller system of CBI equipment without usage of any additional devices.

Technical specifications of the CBI object controller system:

|

Object controller of signals |

Control of signals with light-emitting and light-optical systems or lamp systems with one-filament or two-filament bulbs. |

|

Object controller of points |

Control of electric point machines of different types (including contactless) of AC and DC current (3×220V or 3×380V) |

|

Object controller of relays |

Control of interface relay of different type |

|

Object controller of axle counter system |

Control of detectors of axle counter through a digital interface |

|

Operating temperature range of object controllers |

—40...+70 °С |

|

Relative air humidity |

5...95% |